|

Product Details:

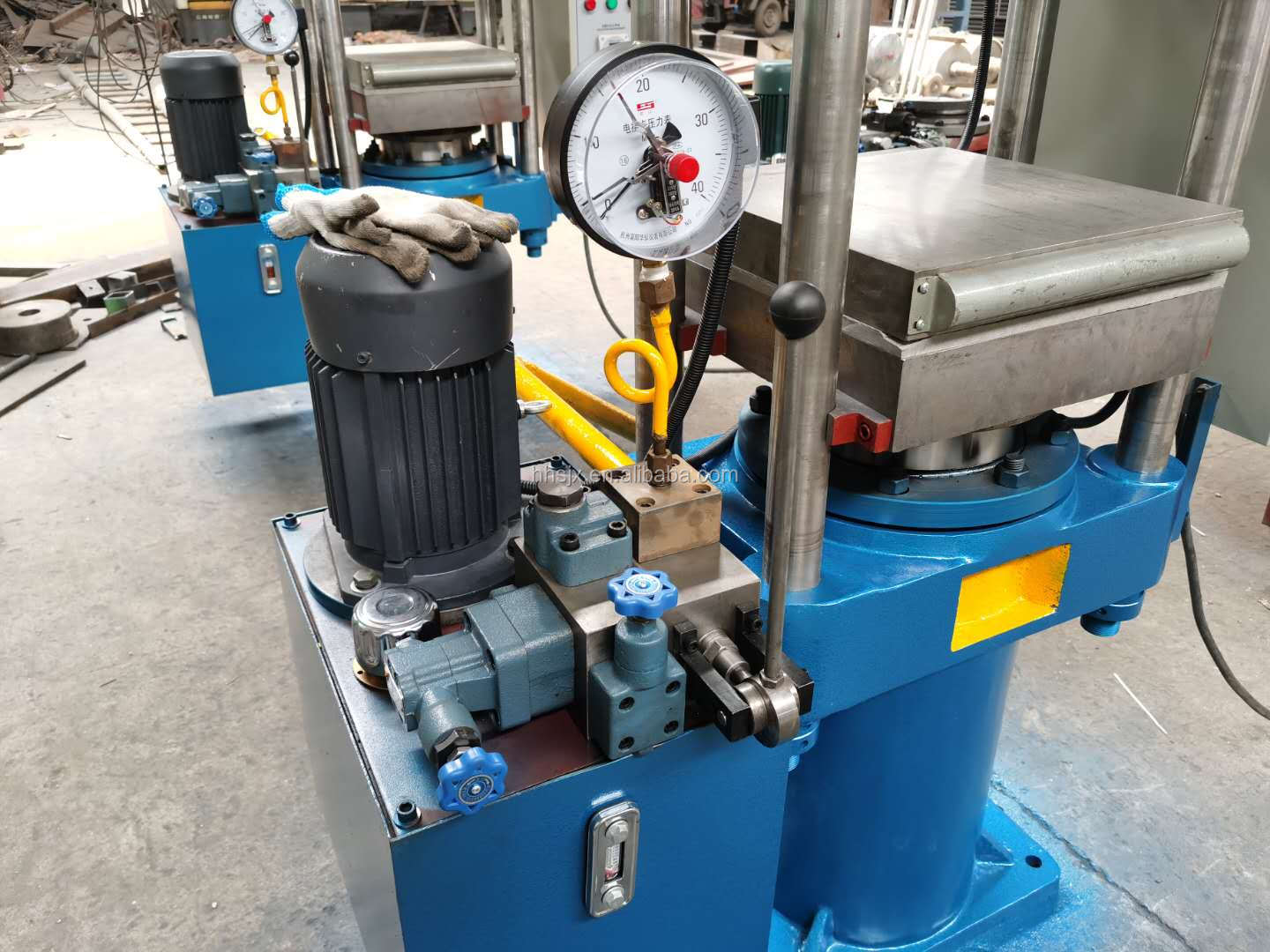

|

| Type: | Vulcanizer | Colour: | All Colour |

|---|---|---|---|

| Voltage: | Customized | Power(W): | 5.5KW |

| Temperature: | Max 300 Degree | Working Layers: | 1-4layers |

| Plates: | 300-2100mm | Hot Plates Material: | Q-235 Material. |

| Heating: | Electricity , Steam Heating , Conduction Oil Heating . | Weight: | 2000 Kg |

| High Light: | Vulcanize Rubber Moulding Machine,Column Vulcanizing Rubber Moulding Machine,Column Vulcanizing Press Machine |

||

This machine consists of heating plate , beam and plate form , cylinder , base , electrical system , etc .it is widely used for heating , vulcanizing and solidifying various kinds of rubber molded product , such as seal , gasket , o rings , etc

1.The machine adopts the semiautomatic control. Worker can set the vulcanzing time , vulcanizing temperature in the cabinet . On finishing vulcanization , machine will alarm and worker can open mold

2.Most spare parts for hydraulic system are from our best domestic brand

3.Machine body casting is made of FCD 50 ductile cast iron ,which is processed by high tensile strength after aging passivation

4.The machine pillars/ columns are made of medium carbon steel , and its hardness can reach HRC55-58

5.The cartridge heater adopts three stages winding, nichrome wire , non-rusty

6.Oil seal are from Japanese NOK and Sakagmi Brand , it is wear-resisitant ,durable and oil tight

7.Main electrical elements are from Schneider France ,which can stabilize machine performance

Parameter

| type | XLB-D350x350x2 | XLB-D400x400x2 | XLB-D500x500x2 | XLB-D600x600x2/4 |

| nominal mold power(mn) | 0.25 | 0.5 | 0.8 | 1 |

| working layer | 2 | 2 | 2 | 2 |

| piston stroke(mm) | 250 | 250 | 250 | 300 |

| plate pressure(Mpa) | 2.04 | 3.13 | 2.4 | 4.94/2.78 |

| main motor power(kw) | 1.5 | 2.2 | 2.2 | 2.2 |

| plate clearance(mm) | 125-200 | 125-200 | 125-200 | 125-250 |

| heating mode | electric oil steam | electric oil steam | electric oil steam | electric oil steam |

| configuration | column | column | column | column |

| electric power(kw) | 1.8 | 2.7 | 3.0 | 2.7/3.6 |

why choose us:

1 manufacturer direct sale, can ensure delivery time and quality.

2 plunger diameter difference is very small,which ensure pressure.

3 our vulcanizing press is equiped with PLC system. automatic controling temperature and pressure, automatic alarm, automatic loading ,emergency stop ,digital readout and son on.

4 low noise, no oil leakage, no pressure off.

5 small temperature difference of hot plate,

Plate temperature difference: ±1°C, which follows the national standard.

6 the parallelism differnce does not exceed ±0.01-0.02mm

7 hot plate use high quality carbon steel Q-235 material.

7 heating method according to your request : electricity , steam heating , conduction oil heating .

8 we can make machine according to the your request.

9 we can give a good discount according to your quantity

Detailed Pictures

![]()

![]()

![]()

![]()

![]()

Contact Person: Miss. Sophie

Tel: +8613573826806