|

Product Details:

|

| Heating Platen Size: | 550X550*4 | Mold Closing ForceF: | 100/120/160T |

|---|---|---|---|

| Plate Clearance: | 150-300mm | Working Layers: | 1 |

| Motor Power: | 5.5/7.5KW | Overall Dimension: | 2200X900X2200mm |

| Weight: | 4000KG | Type: | Vulcanizer,tile Machine |

| Color: | Blue,Customizable | Power Source: | Hydraulic |

| Usage: | Rubber Tile From Waste Tyre Granule, Glue, Colour | Keyword: | Tile Vulcanizing Press |

| High Light: | Rubber Tiles Vulcanizing Press,EPDM Rubber Tiles Vulcanizing Press,Rubber Carpet Pressing Machine |

||

High Efficient Rubber Tiles Vulcanizing Press/rubber carpet pressing machine

Basic introduction of High Efficient Rubber Tiles Vulcanizing Press/rubber carpet pressing machine.

Rubber vulcanizing press applies to all kinds of rubber (natural rubber, EPDM rubber, NBR rubber, synthetic rubber, silicone rubber ext. ) vulcanizing and compression molding.

rubber vulcanizing press can be used to make O ring, sealing parts, oil seal, auto parts, rubber crash pad, rubber air spring, key board, medical rubber parts, rubber bottle stopper, silicone wrist band, water-stop tape, bridge support/bridge bearings, rubber cable, electronics insulators etc..

Configuration of High Efficient Rubber Tiles Vulcanizing Press/rubber carpet pressing machine.

1.The machine adopts the advanced PLC control . The working program can be set in the cabinet and machine will work according to this program

2.Most spare parts for hydraulic system are imported from Taiwan

3.Machine body casting is made of FCD 50 ductile cast iron ,which is processed by high tensile strength after aging passivation

4.The machine pillars/ columns are made of medium carbon steel , and its hardness can reach HRC55-58

5.The cartridge heater adopts three stages winding, nichrome wire , non-rusty

6.Oil seal are from Japanese NOK and Sakagmi Brand , it is wear-resisitant ,durable and oil tight

7.Main electrical elements are from Schneider France ,which can stabilize machine performance

Technical Parameters

![]()

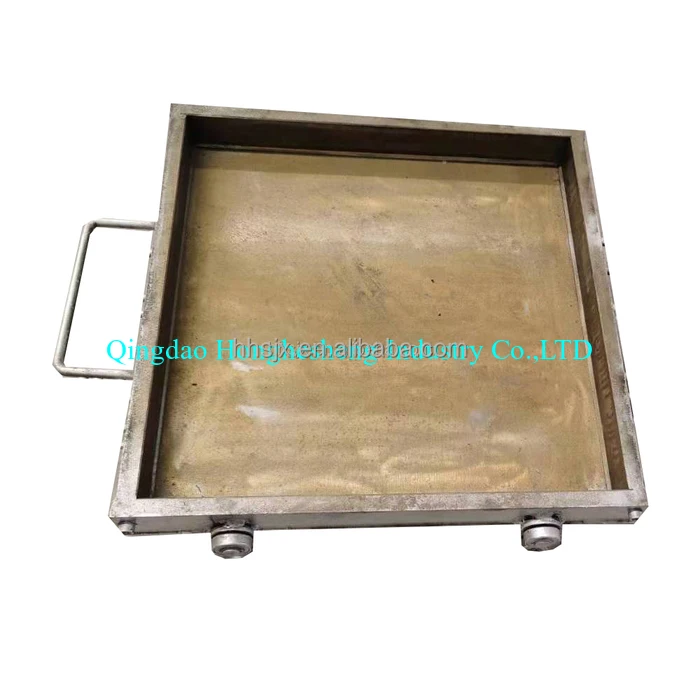

Detailed Pictures

![]()

![]()

![]()

![]()

![]()

![]()

![]()

our working machine in factory,when you visit our factory, we can show you our machine in real production nearby factory.

![]()

![]()

![]()

![]()

![]()

Contact Person: Miss. Sophie

Tel: +8613573826806