|

Product Details:

|

| Heating Platen Size: | 550X550*4 | Mold Closing ForceF: | 100/120/160T |

|---|---|---|---|

| Plate Clearance: | 150-300mm | Working Layers: | 1 |

| Motor Power: | 5.5/7.5KW | Overall Dimension: | 2200X900X2200mm |

| Weight: | 4000KG | Type: | Vulcanizer,tile Machine |

| Color: | Blue,Customizable | Power Source: | Hydraulic |

| Usage: | Rubber Tile From Waste Tyre Granule, Glue, Colour | Keyword: | Tile Vulcanizing Press |

| High Light: | Playground Rubber Mat Vulcanizing Machine,Outdoor Rubber Mat Vulcanizing Machine,Rubber Tile Making Machine 100t |

||

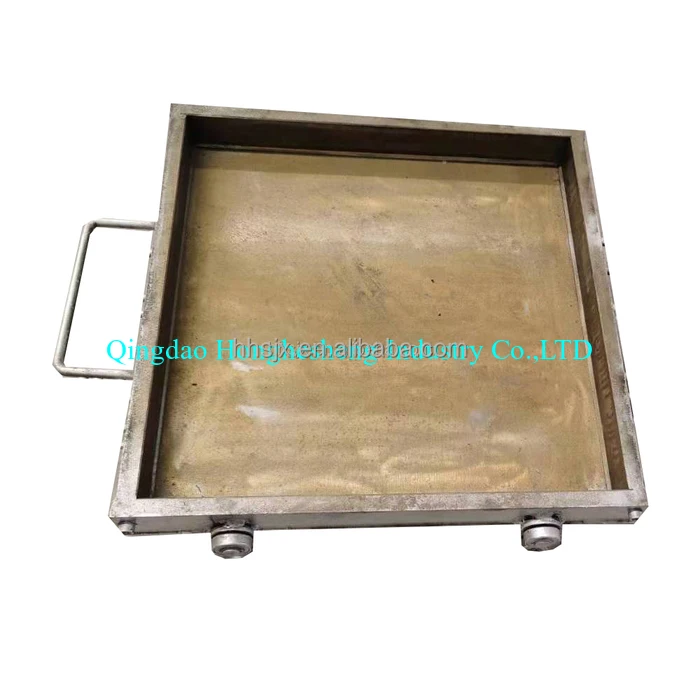

This machine is used to heat , vulcanize and solidify the rubber compound from mixer machine to be 500*500mm and 1000*1000mm rubber tiles .One set molds includes one top mold and two bottom mold . As showed in picture , the machine is equipped with adjustable rail device , which is used to push mold in and out for easy operation

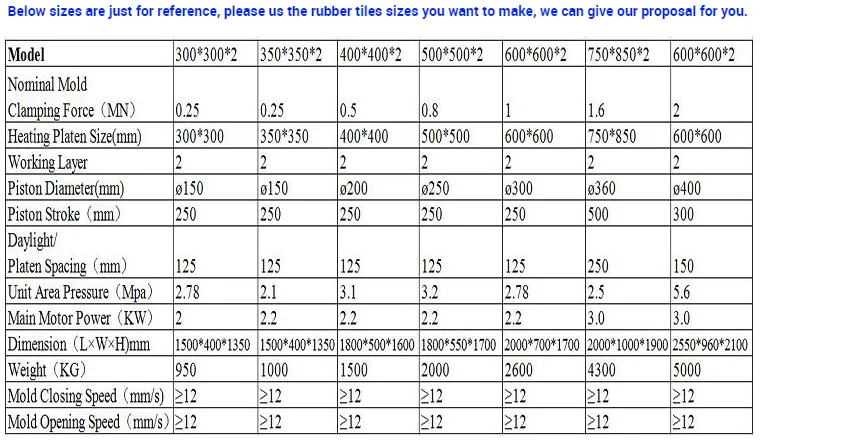

Technical Parameters

Detailed Pictures

![]()

![]()

![]()

![]()

![]()

![]()

![]()

our working machine in factory,when you visit our factory, we can show you our machine in real production nearby factory.

![]()

![]()

![]()

![]()

![]()

Contact Person: Miss. Sophie

Tel: +8613573826806